Introduction

Computer Numerical Control (CNC) technology has revolutionized architectural processes, offering architects and designers unprecedented precision, consistency, and efficiency. Let’s explore how CNC Machines in Architecture & Design are transforming the field.

1. Modeling and Prototyping

Architects use CNC machines to create intricate models and prototypes. Whether it’s testing design concepts or presenting ideas to clients, CNC technology allows architects to visualize their projects before full-scale construction. Akriti Precision Systems’ CNC machines excel in producing detailed and accurate models.

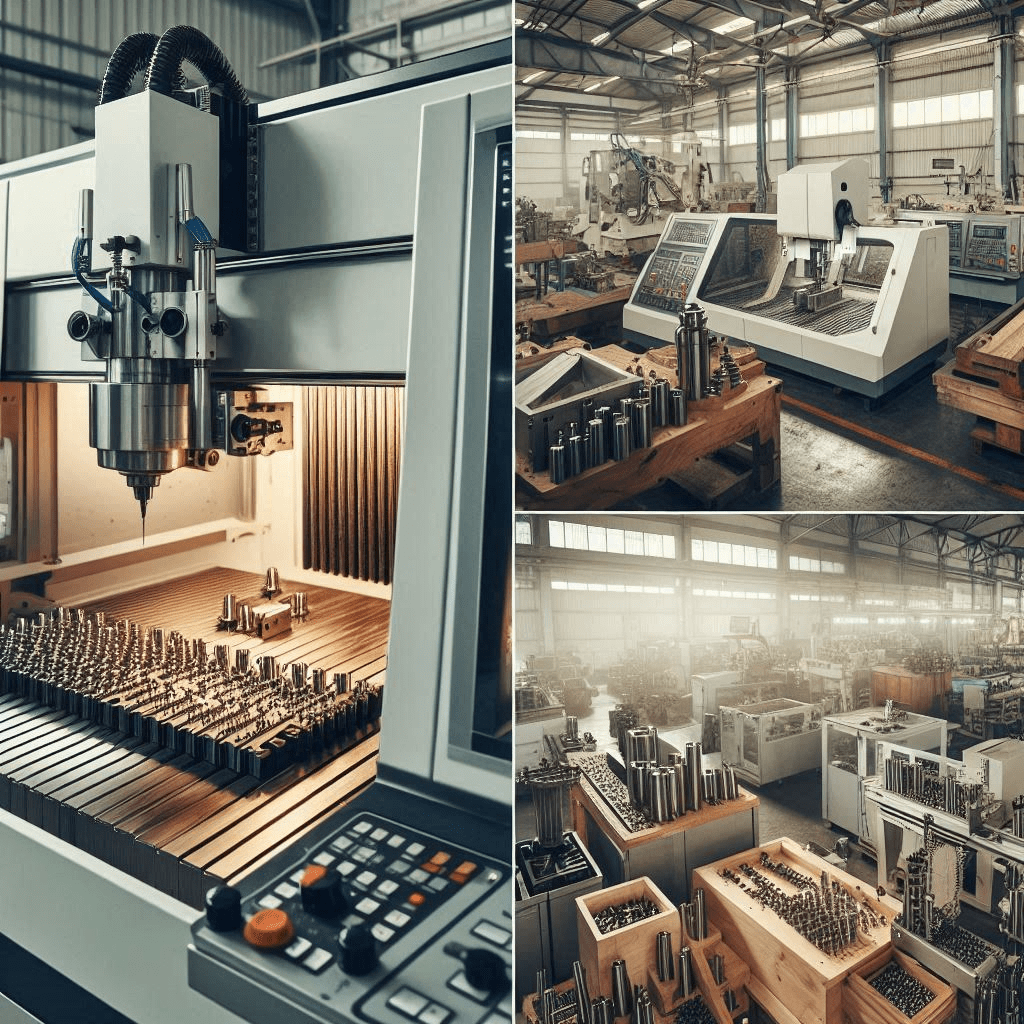

2. Large-Scale Production

CNC machining isn’t limited to prototypes; it plays a crucial role in large-scale production. Architects leverage CNC technology during both the design and construction phases. The advantages include speed, efficiency, and consistent quality. Akriti’s CNC machines ensure precise fabrication, even across projects spanning thousands of miles.

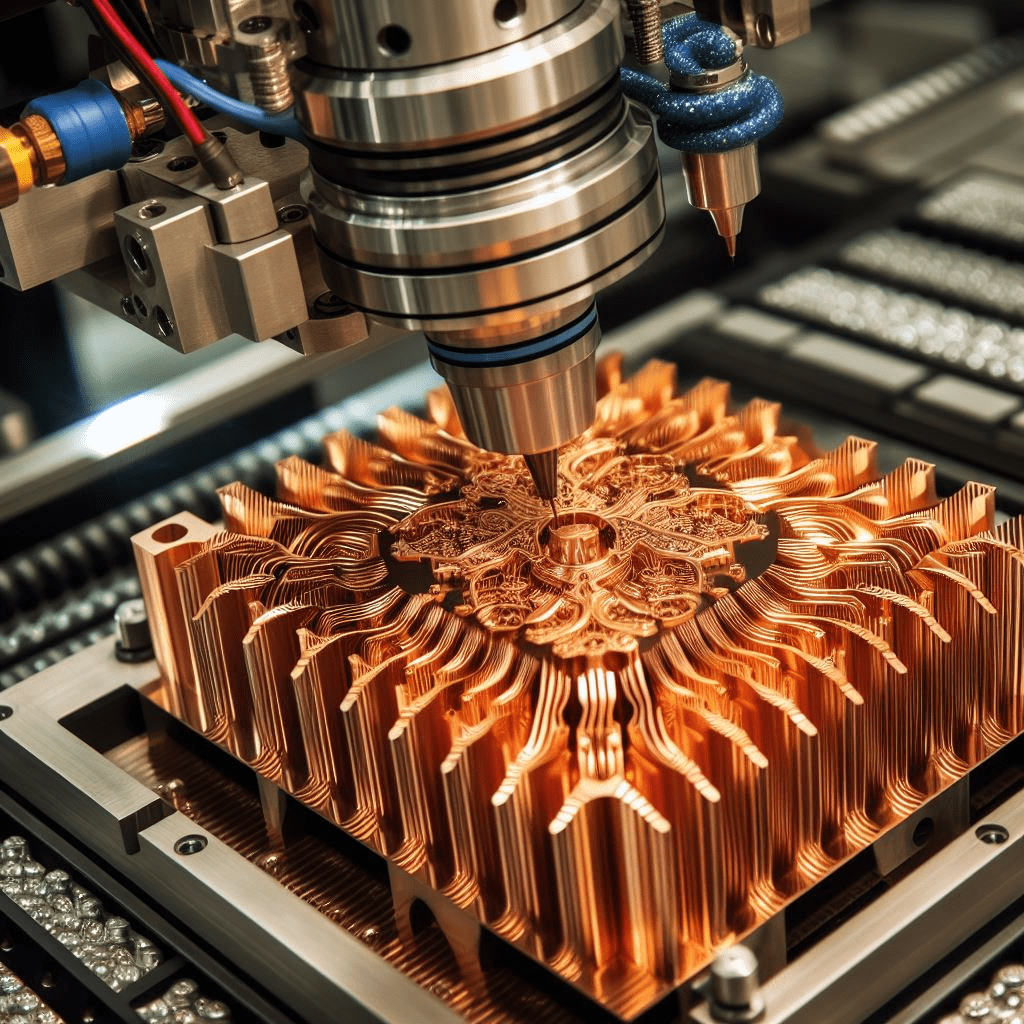

3. Facade Panels

CNC-cut facade panels enhance architectural aesthetics. Intricate patterns, textures, and geometric designs can be precisely carved into materials like wood, metal, or composite panels. Akriti’s CNC machines achieve flawless results, elevating building exteriors.

4. Custom Stairs and Furniture

Architects use CNC machines to craft custom staircases and furniture pieces. From ornate balustrades to ergonomic chairs, CNC technology allows for intricate detailing and seamless assembly. Akriti’s CNC machines ensure both functionality and beauty.

5. Partitions and Wall Art

CNC-cut partitions and wall art add character to interior spaces. Whether it’s decorative screens, room dividers, or feature walls, architects appreciate the precision and versatility of CNC machining. Akriti’s machines enable intricate designs that captivate occupants.

6. Cladding Solutions

Architectural cladding, whether for exterior or interior surfaces, benefits from CNC precision. Akriti’s CNC machines create uniform cladding elements, enhancing building aesthetics and durability.

Unique Features of Akriti’s CNC Machines

- High Precision: Akriti’s CNC machines achieve micron-level accuracy, ensuring flawless cuts and carvings.

- Easy to use Software: Their control software is easy to learn and use by anyone.

- Material Compatibility: Akriti’s machines handle various materials, from wood to non-ferrous metals and composites.

- Customization: Architects can tailor CNC programs to their specific design requirements.

In summary, CNC machines empower architects to push creative boundaries while maintaining precision. Akriti Precision Systems stands at the forefront of this technological revolution, providing cutting-edge solutions for architectural excellence.

Visit our website – Link

Our Youtube Channel – Link

CNC Machines in Architecture & Design