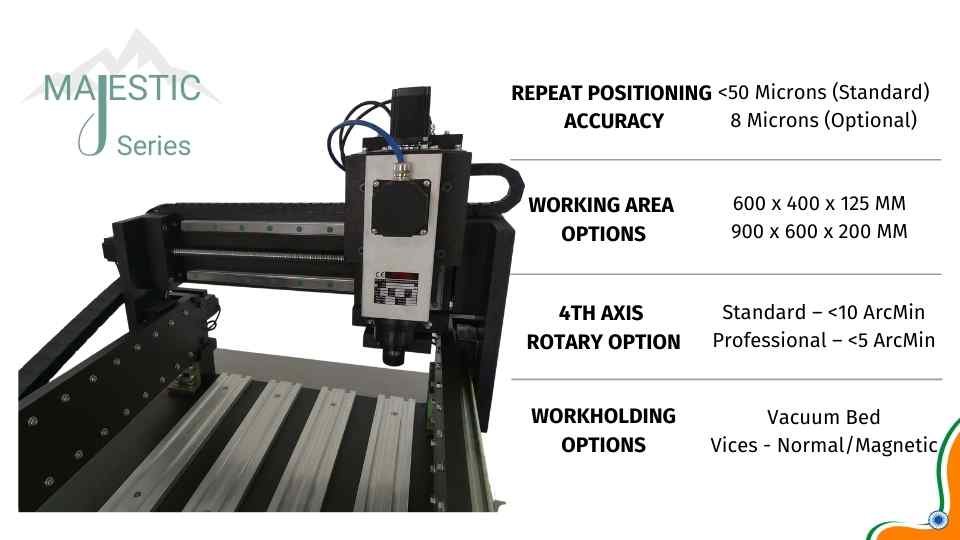

In the world of CNC machining, the quest for perfection is relentless. Manufacturers and fabricators are constantly seeking ways to enhance precision, speed, and quality, especially when it comes to cutting aluminium. Enter the Majestic Series from Akriti Precision Systems, a game-changer in the industry, thanks to its innovative Composite Superstructure.

The Role of Composite Superstructure

The Majestic Series stands out with its Composite Superstructure, a pioneering design that incorporates carbon fibre and fibre glass in a composite sandwich structure1. This ingenious approach offers several advantages over traditional steel or aluminium framed CNC machines.

Lightweight Yet Robust

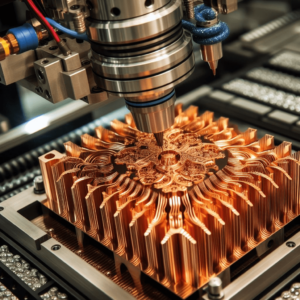

Firstly, the composite material significantly reduces the overall weight of the machine. This reduction translates to increased agility and faster cycle times without compromising on strength or durability. Consequently, operators can achieve better aluminium cuts with greater efficiency.

Thermal Stability for Consistent Precision

Moreover, the thermal stability of the composite superstructure ensures minimal thermal drift. This means that even during extended machining operations, the Majestic Series maintains consistent precision, a critical factor when working with aluminium2.

Durability That Lasts

Another remarkable benefit is the resistance to metal fatigue. Unlike metal structures that can suffer from sagging or hogging over time, the composite superstructure of the Majestic Series remains unaffected by such deformations, ensuring a longer lifespan and sustained accuracy3.

Maintenance Made Easy

Furthermore, the composite material is immune to rust and corrosion, which plagues metal machines. This immunity leads to lower maintenance costs and less downtime, allowing for uninterrupted production cycles4.

A Warranty That Speaks Volumes

Akriti Precision Systems is so confident in the durability and performance of their composite superstructure that they offer a lifetime warranty on it. This commitment underscores the reliability and quality that the Majestic Series brings to the table1.

Conclusion

The Majestic Series of CNC machines by Akriti Precision Systems is not just a tool; it’s a revolution in aluminium machining. The composite superstructure is at the heart of this innovation, providing a lightweight, thermally stable, and durable solution that stands the test of time. For those looking to achieve better aluminium cuts, the Majestic Series is the answer, offering a blend of precision, speed, and reliability that is unmatched in the industry. Experience the composite superstructure difference with Akriti’s Majestic Series and take your aluminium machining to new heights.