Crafting Precision: How CNC Machines Revolutionize Lens and Mirror Making

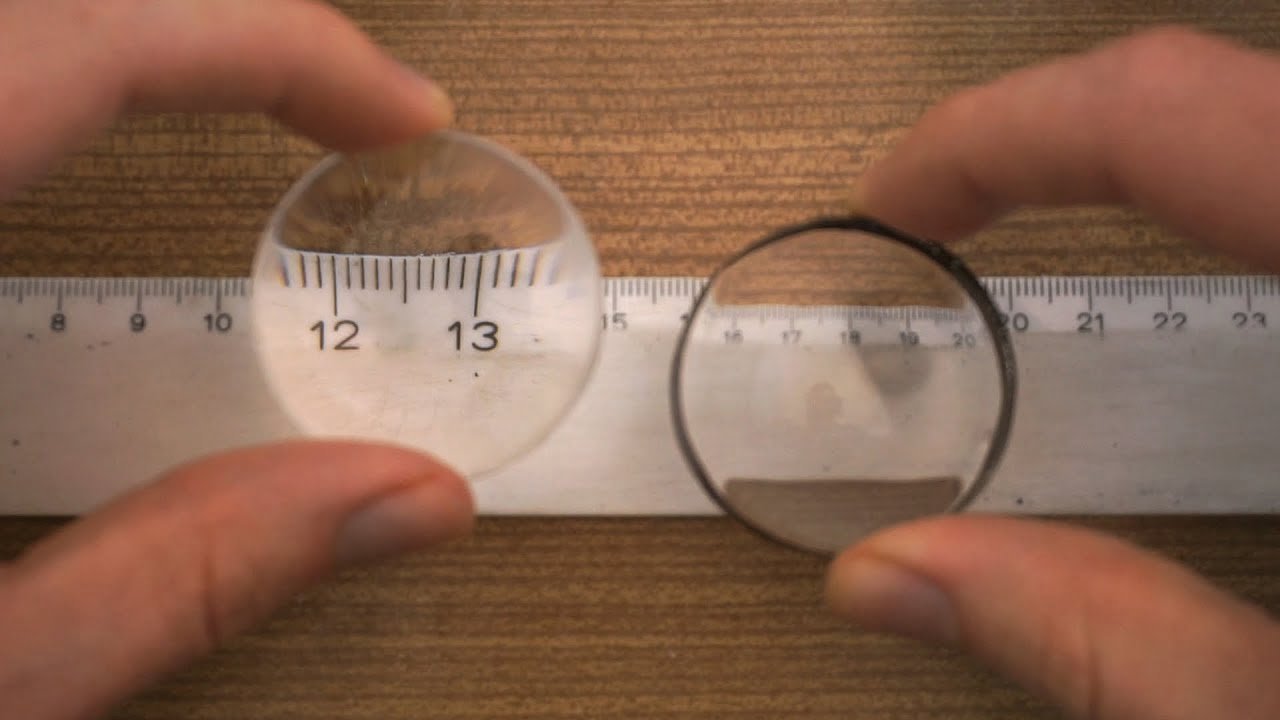

Imagine needing a custom lens with a specific focal length for a unique experiment. Traditionally, this might have involved lengthy procurement processes or expensive, pre-made options. But enter the exciting world of CNC machining, where crafting high-precision optics is becoming more accessible than ever.

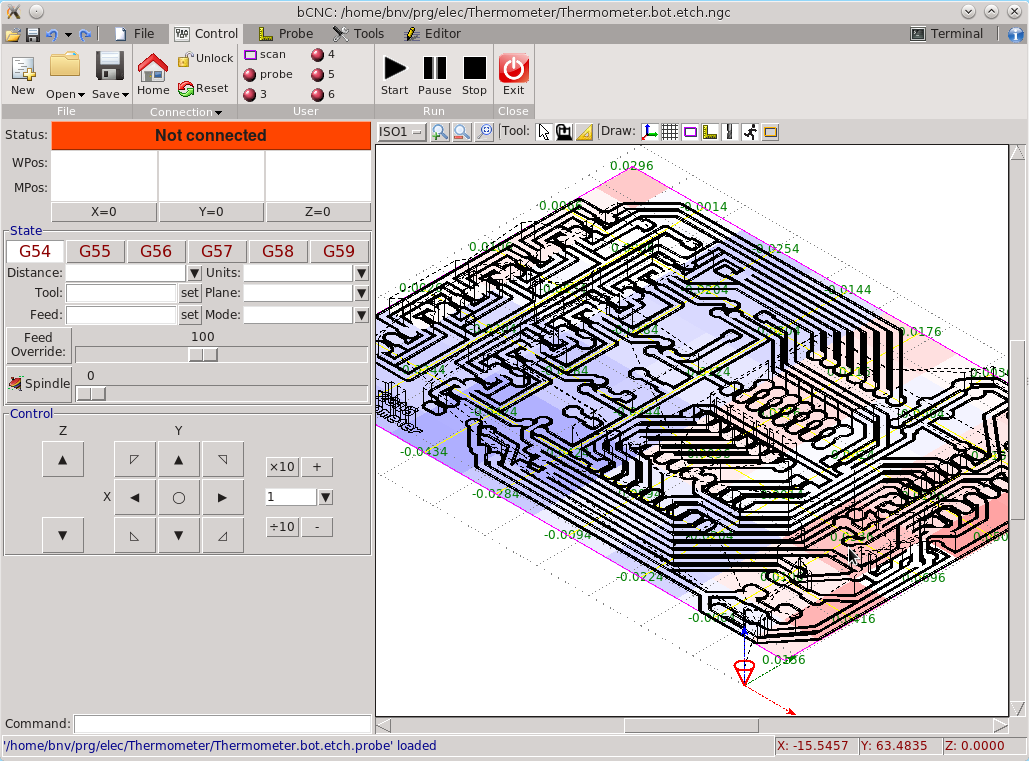

CNC, or Computer Numerical Control, machining utilizes computer-guided tools to create intricate shapes from various materials. This technology is revolutionizing the way we create lenses and mirrors. Here’s why:

-

Unmatched Precision: CNC machines boast incredible accuracy, down to microns, allowing for the creation of lenses and mirrors with precise focal lengths crucial for scientific experiments and specialized applications.

-

Customizable Creations: Gone are the days of limited options. CNC machining allows for the creation of lenses and mirrors with specific focal lengths and shapes tailored to your exact needs. This opens doors for innovative experiments and groundbreaking research.

-

Streamlined Production: CNC machining streamlines the lens and mirror manufacturing process compared to traditional methods. This translates to faster turnaround times and potentially lower costs, making it an attractive option for researchers and hobbyists alike.

Beyond the Lab: Applications Abound

While CNC machining shines in scientific endeavors, its applications extend far beyond the lab. Here are a few examples:

- Custom Eyewear: Imagine perfectly tailored eyeglasses or sunglasses with lenses crafted to your specific vision needs.

- Optical Instruments: CNC machining can create precise lenses and mirrors for telescopes, microscopes, and other optical instruments, enhancing their capabilities.

- Artistic Expression: Artists and designers can utilize CNC-machined lenses and mirrors to create unique light installations and sculptures, pushing the boundaries of artistic expression.

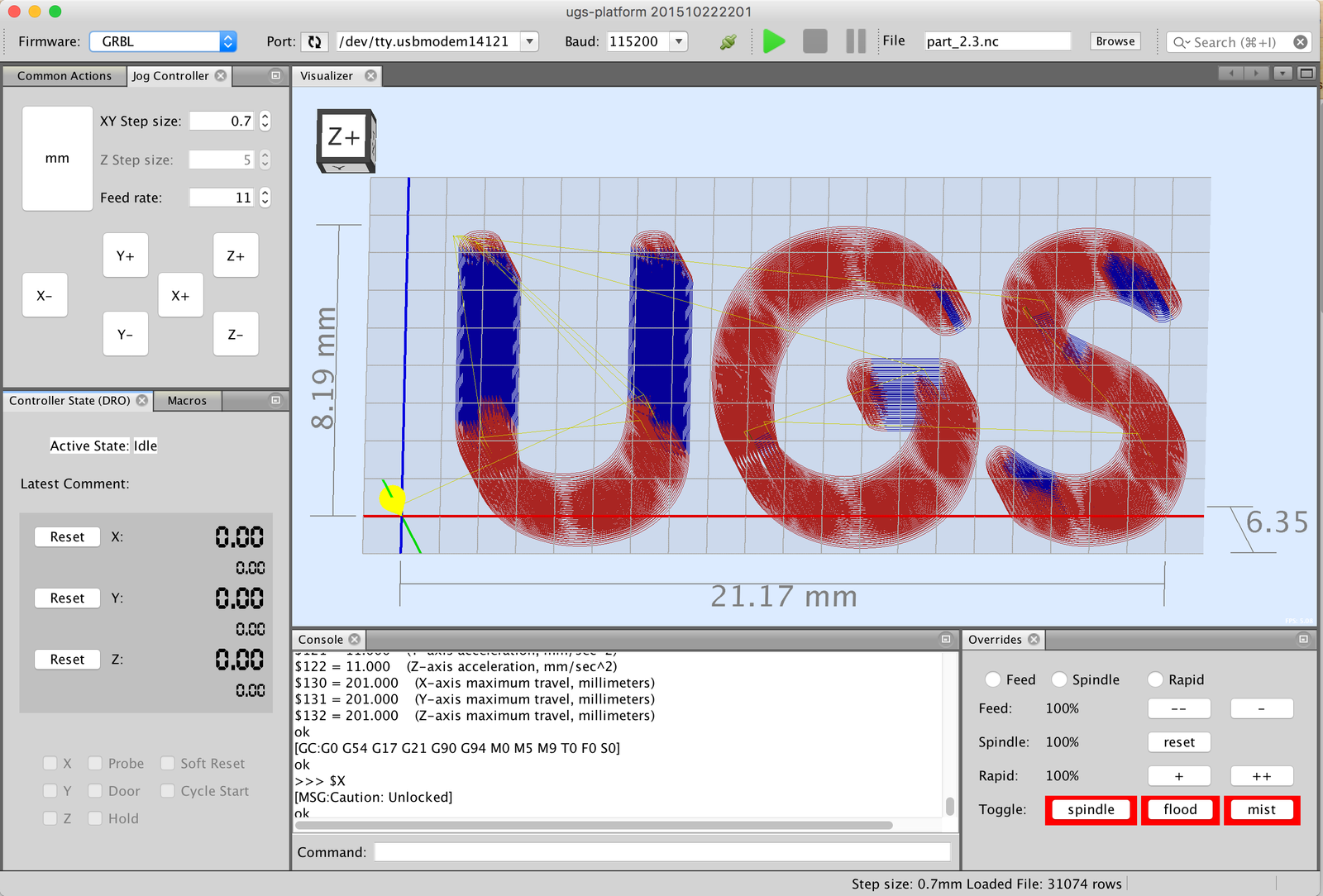

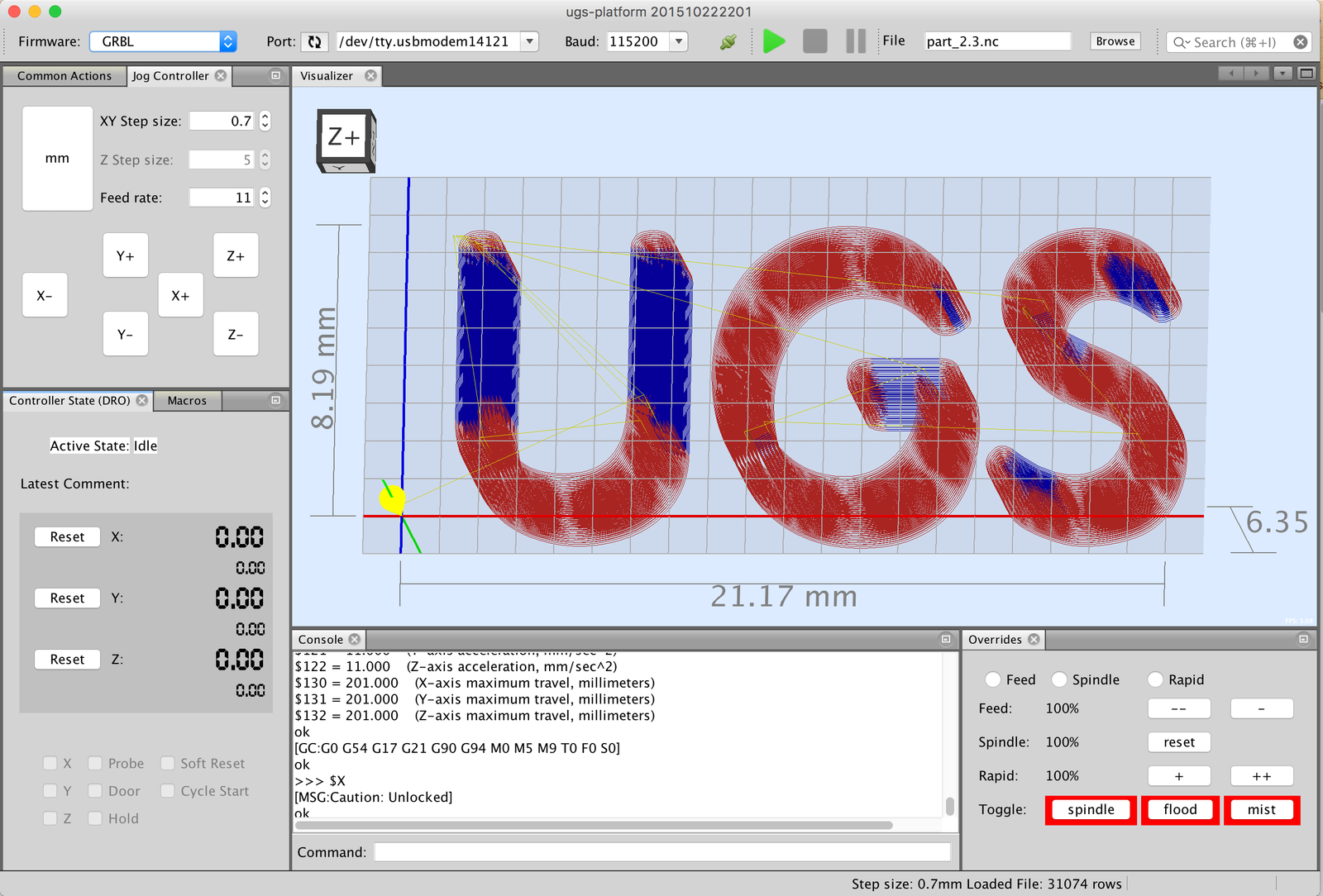

A few video examples are given below.

Lens making with a CNC – Part 1

Lens making with a CNC – Part 2

Another Example

The internet has a lot to offer as there are several DIY ( Do It Yourself) innovators who share their work and sometimes even designs.

Just search and you are certain to get a few hits.

Here are a few resources to get you started with designing and cutting your own projects. Laser cutting projects can also be modified and used for CNC’s.

1) 3Axis.co (Free) – https://3axis.co/laser-cut/toys/

2) MakeCNC (Paid) – https://www.makecnc.com/browse-store/premium-patterns/

3) DesignsCNC (Free) – https://designscnc.com/category/animals/

* These links are being provided as reference only. Akriti Precision Systems does not own any content given on these links and is not responsible for their accuracy, availability etc.

Ready to fabricate your own lenses and mirrors? Explore our selection of high-precision CNC machines built for optical applications! Visit https://akriti.tech to learn more.