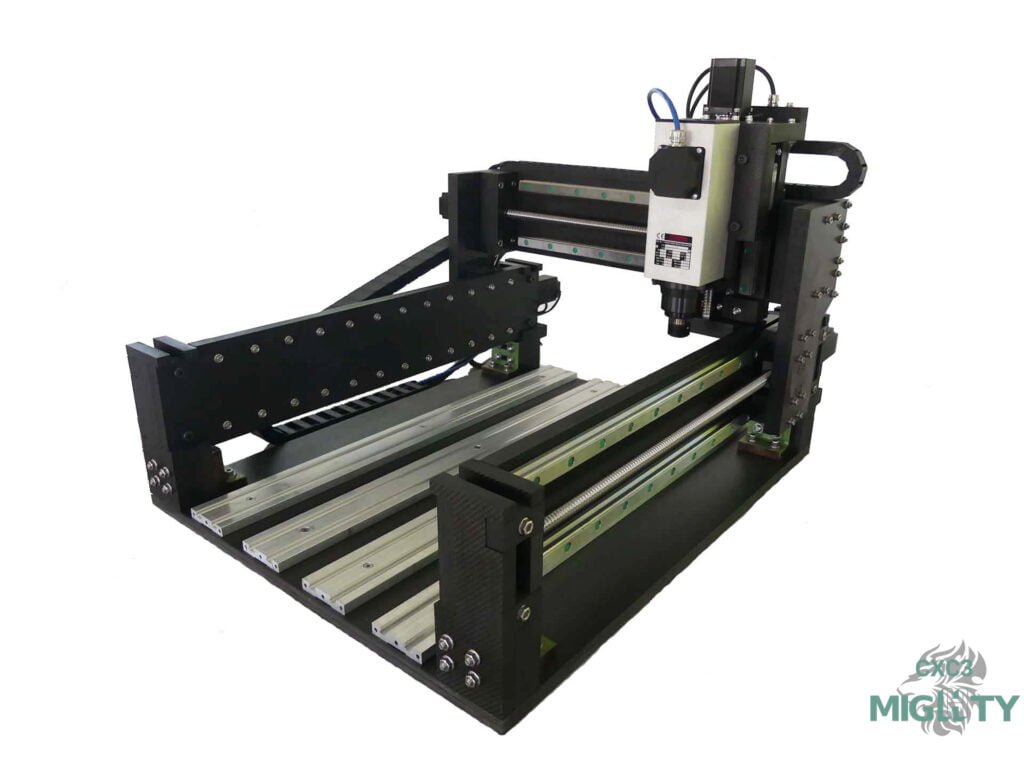

In the ever-evolving world of CNC machining, choosing the right machine and partner is crucial for success. Akriti Precision Systems [Akriti Precision Systems, https://akriti.tech] stands out as a leading provider in India, offering a compelling combination of quality, precision, innovation, and exceptional customer support. But what exactly sets them apart & how do akriti CNC machines Power Your Precision? Let’s delve into 10 key questions that highlight the advantages of partnering and choosing Akriti Precision Systems for your CNC machining needs:

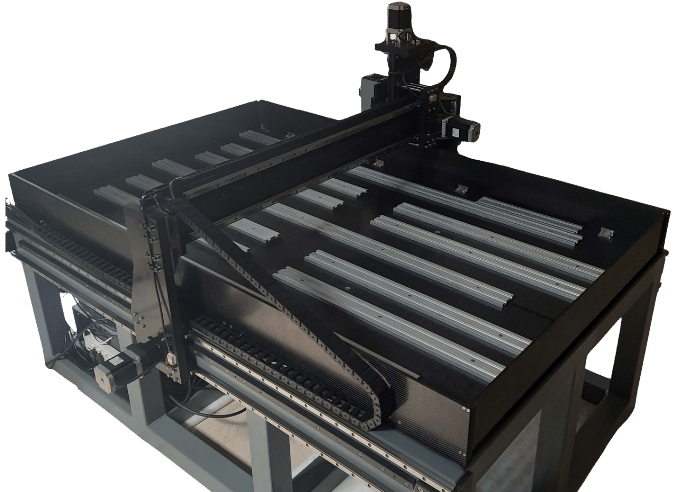

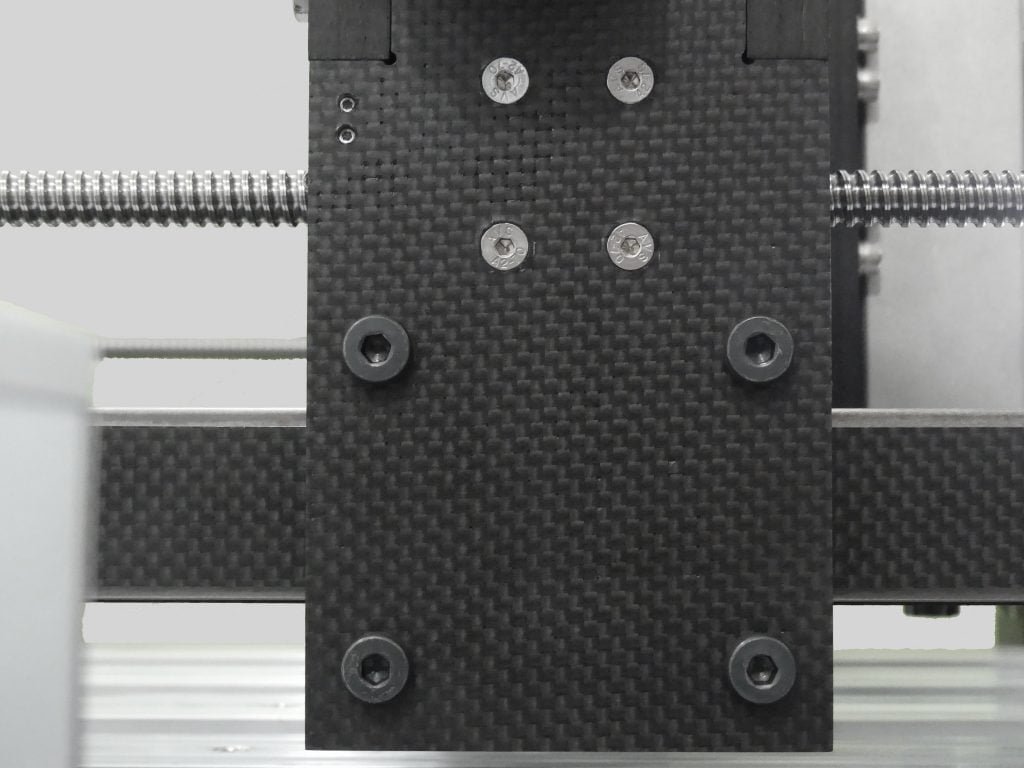

1. Are You Looking for Unmatched Durability and Reliability?

Akriti’s machines are built to last. Their industry-leading warranty package includes:

- One Year Full Warranty: Ensuring peace of mind for all parts during the initial year.

- Optional Extended Warranty: Extend coverage for up to 10 years that can be procured in 1-3 year blocks, tailoring protection to your specific needs.

- Lifetime Superstructure Warranty: Enjoy a lifetime guarantee against corrosion, rust, bending, sagging, or hogging. Your machine’s structural integrity is never a concern.

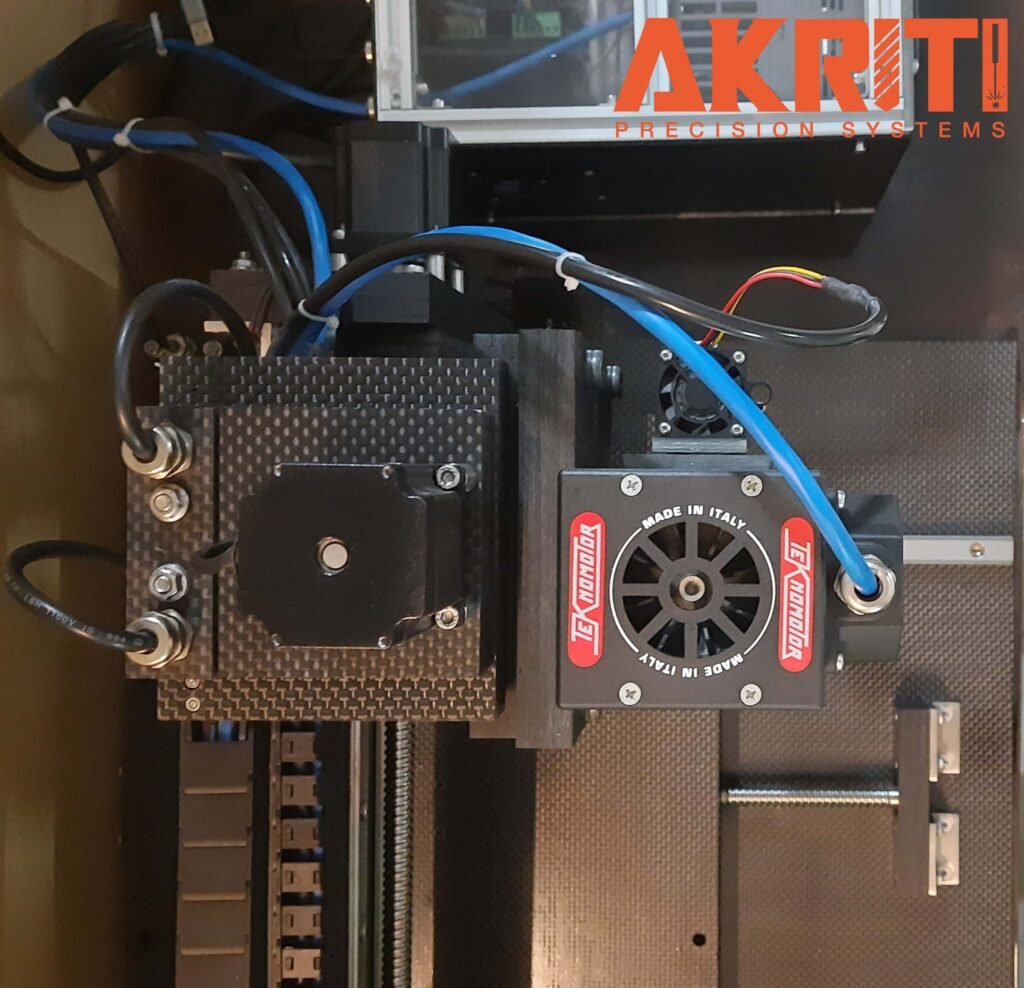

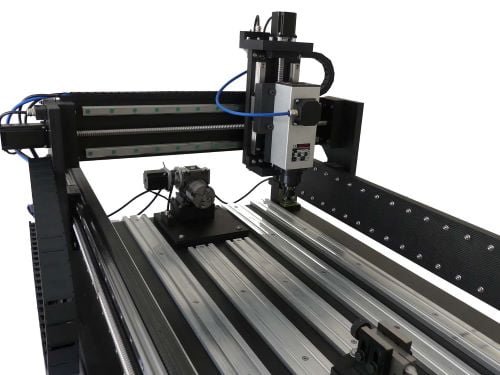

2. Do You Need Precision at Your Fingertips?

Akriti machines utilize high-performance Teknomotor spindles, renowned for their exceptional engineering and 40-year legacy. This translates to superior cutting power, accuracy, and machine performance.

3. Is 24/7 Operation Essential for Your Workflow?

Akriti’s CNC machines are certified for continuous operation, ensuring they can handle even the most demanding production schedules. Maximize your productivity without worrying about downtime.

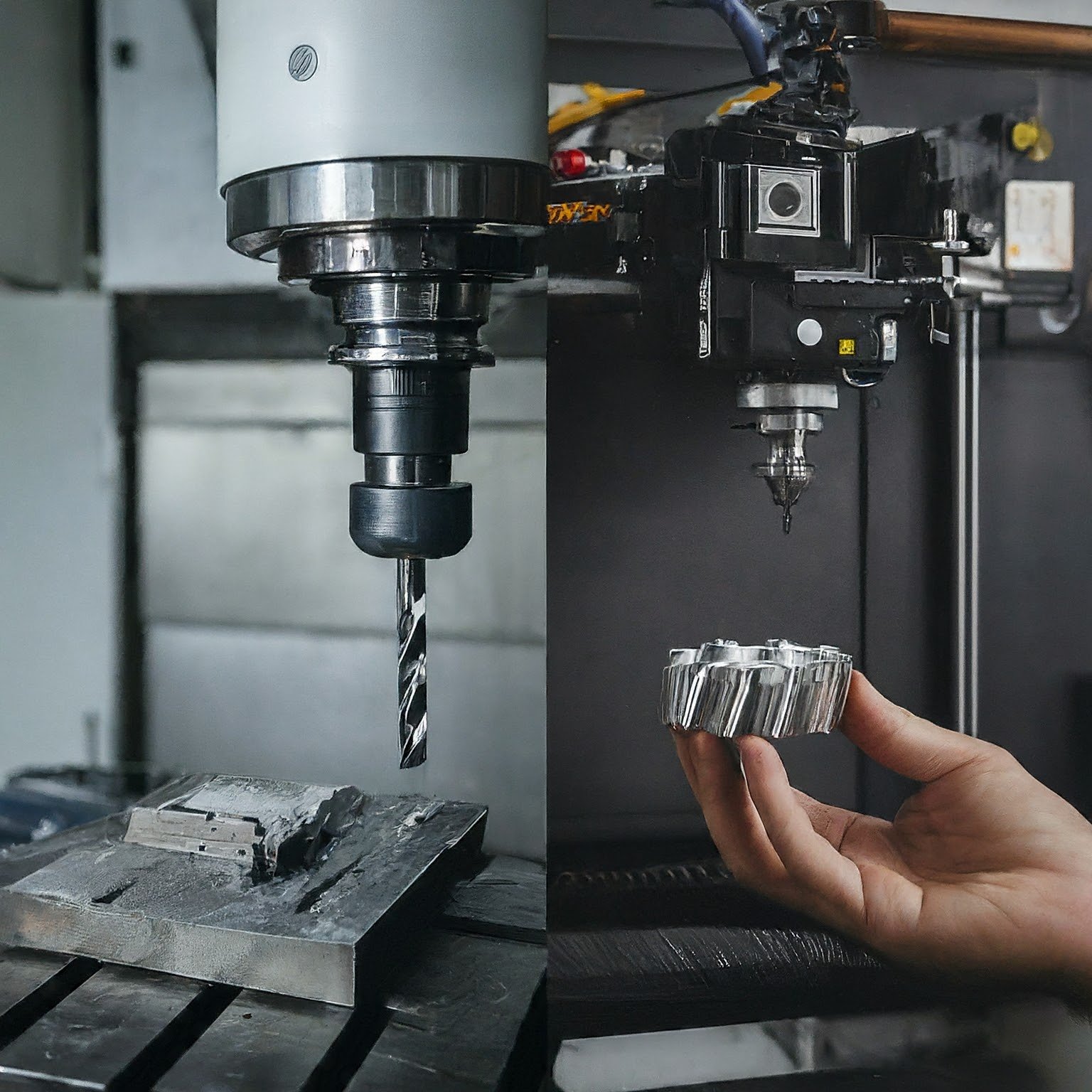

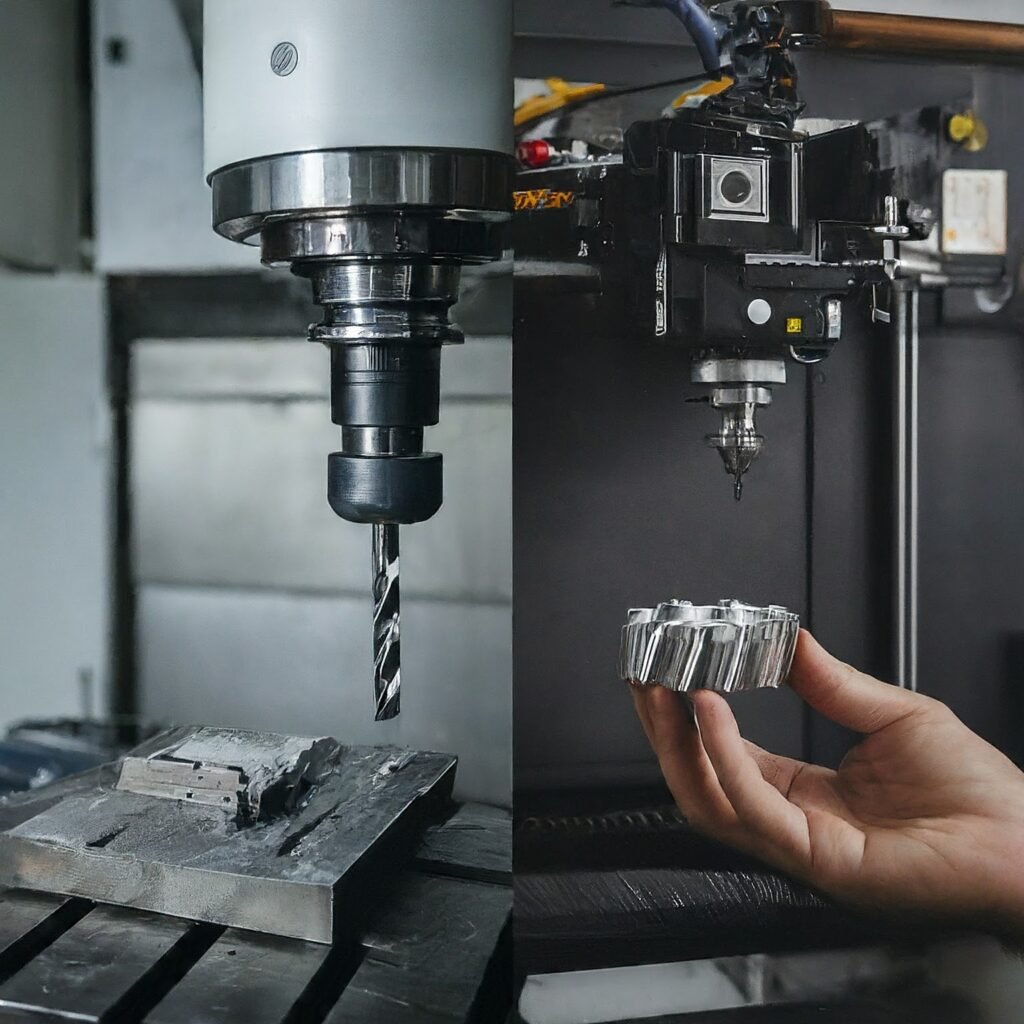

4. How Important is Guaranteed Accuracy to Your Projects?

Akriti prioritizes precision. Their standard machines boast a guaranteed repeat positioning accuracy of less than 50 microns and customizable up to 3.5 microns even.. This meticulous level of detail ensures your parts meet the highest quality standards.

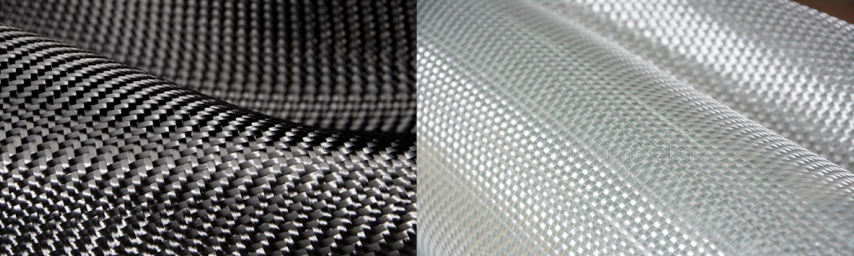

5. Are You Concerned About Sourcing Parts from Different Countries?

Akriti champions transparency. Their machines boast:

- ZERO Chinese Parts: Eliminate concerns about quality and potential compatibility issues.

- 75% Made in India Parts: Support local manufacturing while enjoying exceptional quality.

- 25% Parts Sourced from Italy, Germany, Japan, Taiwan, France & Korea: Benefit from globally recognized components known for their performance and reliability.

6. What Level of Accuracy Do Your Projects Demand?

Akriti offers a range of machines with varying accuracy levels, from a standard 50 microns to an exceptional 3.5 microns. Choose the machine that perfectly aligns with the precision requirements of your projects.

7. Are You a New Entrepreneur Looking for Guidance?

Akriti goes beyond simply selling machines. They offer comprehensive after-sales support and training resources to empower aspiring entrepreneurs. Get the guidance you need to navigate the world of CNC machining with confidence.

8. Is Financing a Consideration for Your Purchase?

Akriti understands the financial realities of starting a business. They work with you to explore financing options that make acquiring your ideal CNC machine a smooth and accessible process.

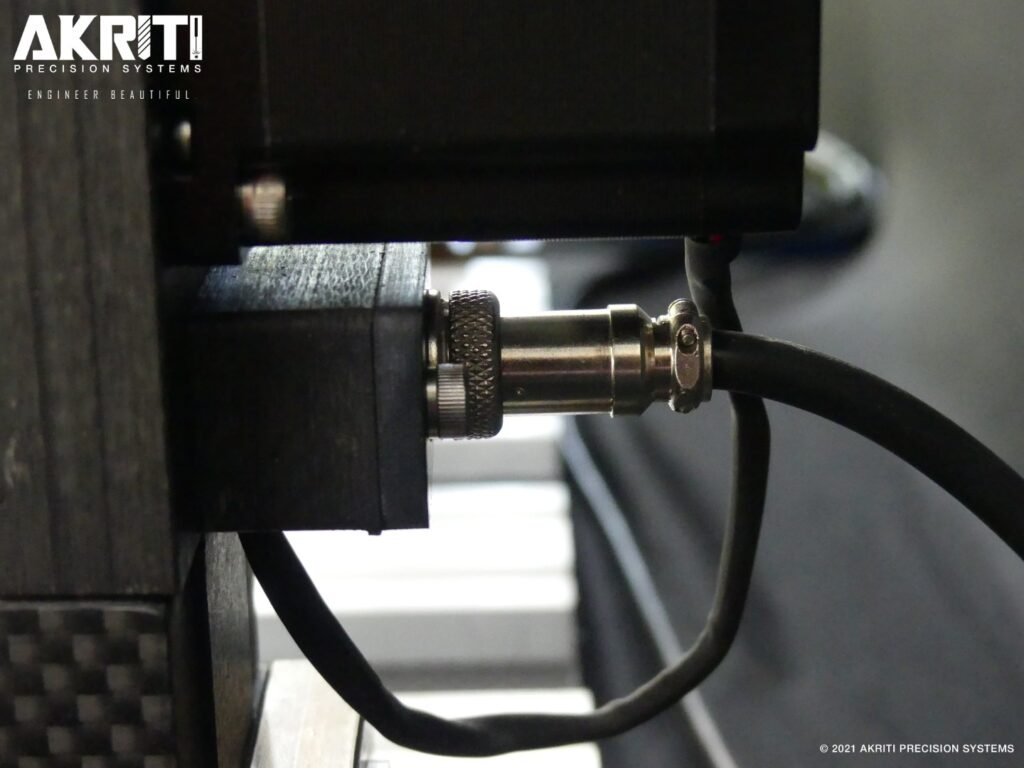

9. Do You Value a User-Friendly Interface and Efficient Operation?

Akriti machines are designed with user-friendliness in mind. Their intuitive control systems minimize downtime associated with complex setups and operation, allowing you to focus on creating.

10. How Important is Customer Support to Your Long-Term Success?

Akriti prioritizes building long-term relationships with their customers. Their dedicated support team is readily available to answer your questions and address any technical concerns that may arise.

In conclusion, Akriti Precision Systems isn’t just about selling machines; they’re about empowering your success in the dynamic world of CNC machining. From unparalleled machine quality, precision to exceptional customer support and expert guidance, Akriti offers a comprehensive package that sets them apart.

Ready to elevate your machining capabilities and turn your vision into reality? Explore Akriti Precision Systems’ website today and discover the perfect Akriti CNC Machines, to Power Your Precision, to fuel your creative and entrepreneurial journey!