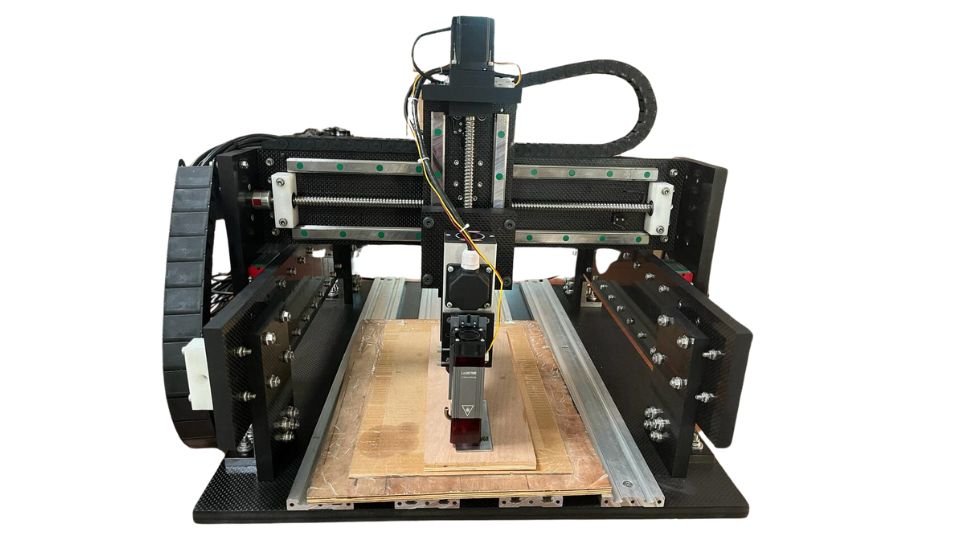

In today’s fast-paced world of woodworking, precision, speed, and versatility are key factors that set apart successful projects from mediocre ones. Whether you’re a seasoned craftsman or a hobbyist, finding the right small CNC router machine for wood working is essential for achieving intricate designs and perfect finishes. Among the top contenders in the market, the CXC4 Majestic XL Pro by Akriti Precision Systems Private Limited, Bangalore, stands out as an exceptional choice for those who demand unparalleled accuracy and capability in their woodworking endeavors. In this ultimate guide, we’ll explore the key features, benefits, and reasons why the CXC4 Majestic XL Pro is the ideal small CNC router machine for woodworking, particularly in the realms of relief art and detailed sculptures.

Why Precision Matters in Woodworking

Woodworking is as much about art as it is about craftsmanship. When creating intricate designs or sculpting detailed reliefs, the slightest deviation can compromise the entire project. Precision in woodworking ensures that every cut, curve, and detail is executed exactly as envisioned. For this reason, the right CNC router machine must offer repeatable accuracy to the highest degree.

The CXC4 Majestic XL Pro excels in this regard, boasting a remarkable repeat positioning accuracy of less than 50 microns. This level of precision is essential for both relief art and small rounded sculptures, where even the tiniest misalignment can detract from the final piece’s beauty and symmetry.

Introducing the CXC4 Majestic XL Pro

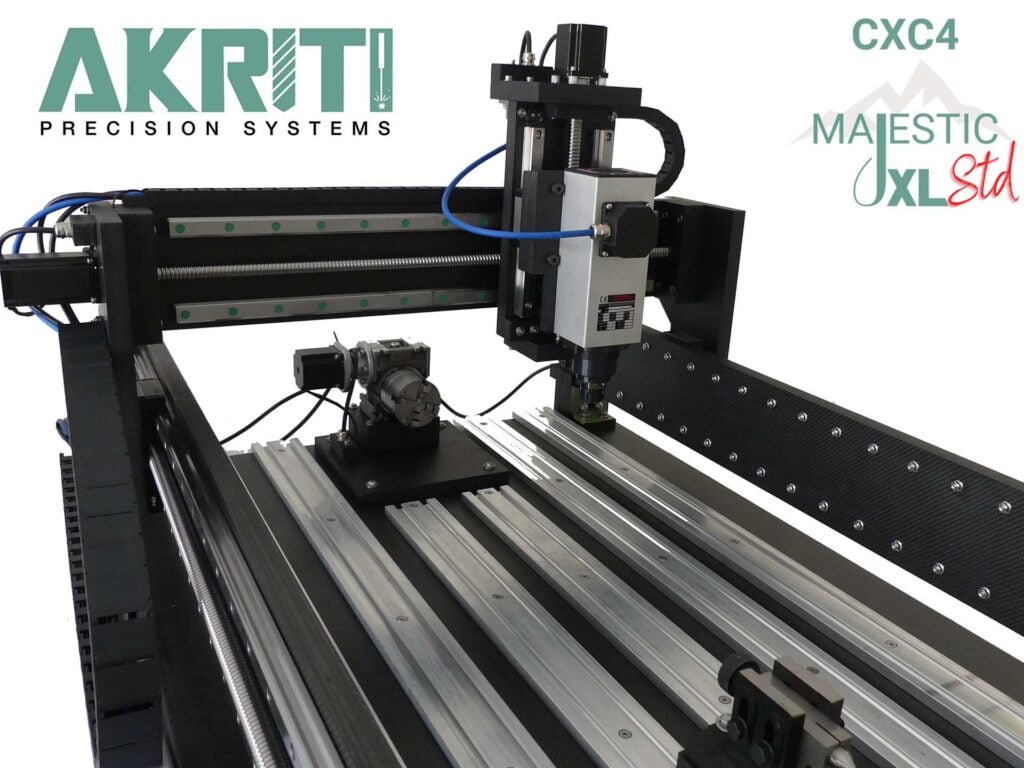

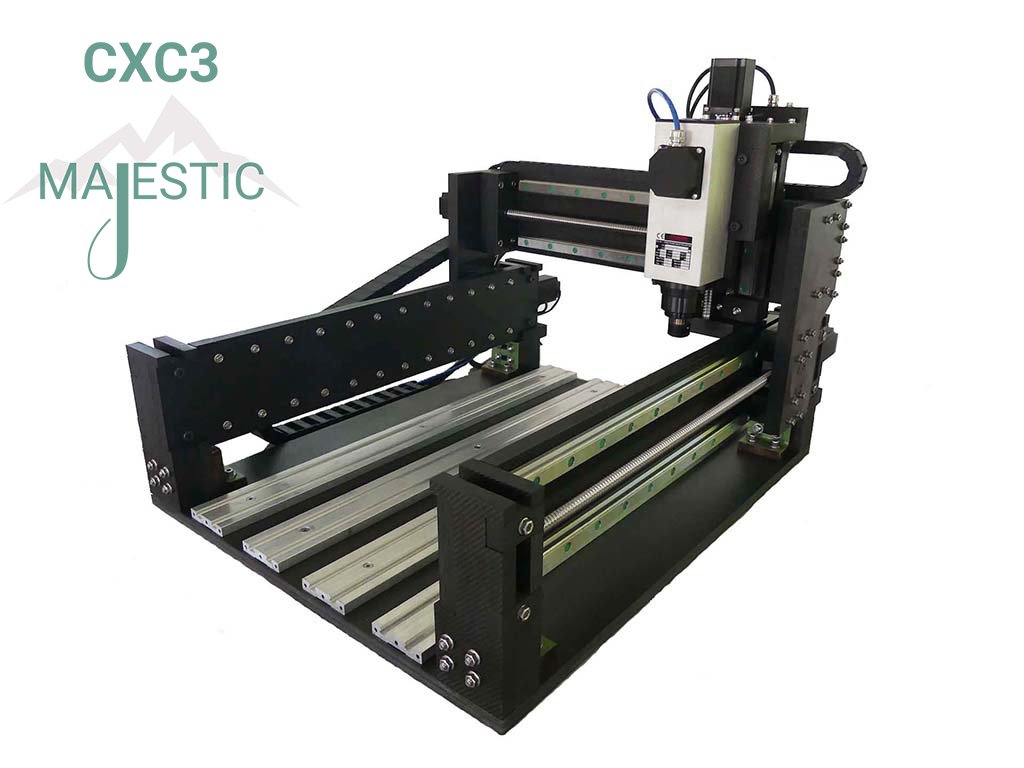

The CXC4 Majestic XL Pro is a high-performance small CNC router designed specifically for woodworking, engineered by Akriti Precision Systems Private Limited in Bangalore. This machine is tailored for artisans who require extreme detail and precision in their work. Its compact design, coupled with advanced features, makes it an ideal tool for creating both relief art in wood and small rounded sculptures.

Key Features of the CXC4 Majestic XL Pro

- High Precision with Sub-50 Micron Repeatability

- The CXC4 Majestic XL Pro ensures that every movement of the cutting tool is executed with a repeat positioning accuracy of less than 50 microns. This precision is critical for achieving detailed and consistent results, especially in complex woodworking tasks like relief carving and sculpting.

- Minimal Backlash for Superior Accuracy

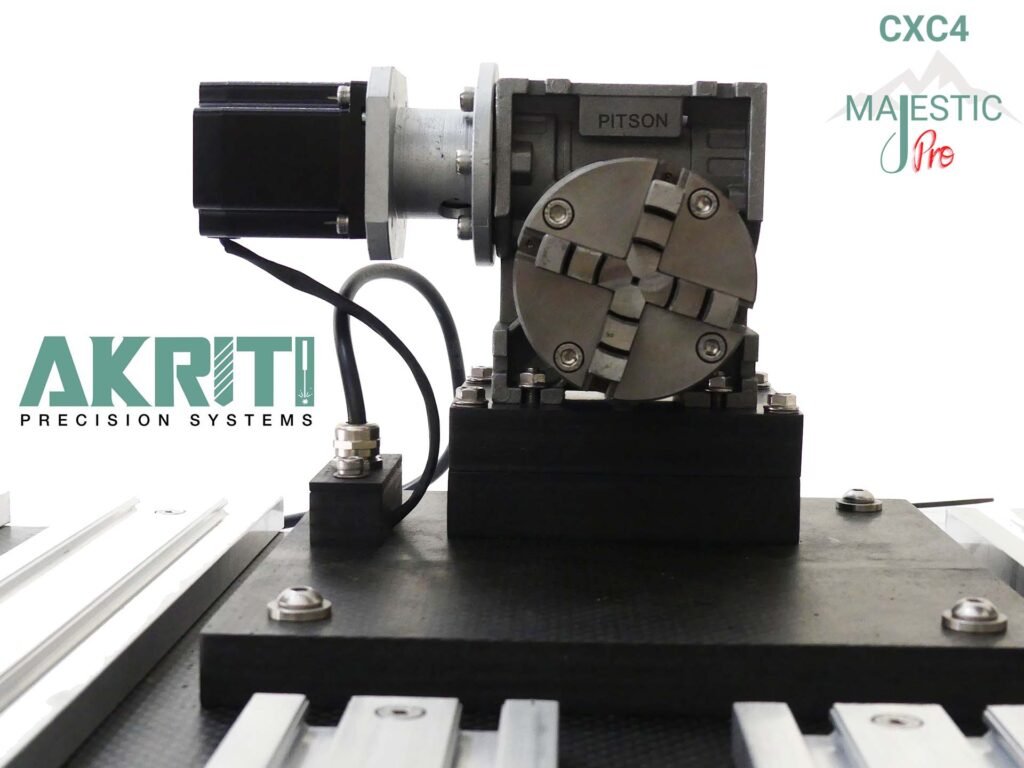

- The machine’s gearbox features a backlash of less than 5 arc minutes, significantly reducing any play or movement in the drive system. This minimal backlash translates to greater accuracy and consistency in the final product, particularly when working on intricate designs.

- Full 3 and 4-Axis Operations

- The CXC4 Majestic XL Pro offers both 3-axis and 4-axis operations, giving woodworkers the flexibility to execute a wide range of projects. Whether you’re crafting detailed reliefs or sculpting rounded forms, the machine’s multi-axis capability ensures you can achieve the desired result with precision.

- Compact Design Optimized for Speed and Accuracy

- Despite its small footprint, the CXC4 Majestic XL Pro is built to deliver fast, accurate cuts without compromising on quality. Its compact design makes it an ideal choice for workshops with limited space, while still offering the power and functionality needed for professional-grade woodworking.

The Importance of Multi-Axis Functionality

In the world of CNC machining, the number of axes a machine can operate on significantly impacts its versatility. The CXC4 Majestic XL Pro’s full 3 and 4-axis operations enable woodworkers to achieve complex geometries and detailed carvings that would be challenging or impossible with simpler machines.

For relief art, the 3-axis capability allows the router to move in the X, Y, and Z directions, creating depth and dimension in the wood. Meanwhile, the 4-axis capability introduces rotation, which is essential for carving rounded sculptures. This additional axis enables the machine to handle the wood from multiple angles, resulting in smooth, continuous cuts that are crucial for detailed and lifelike sculptures.

Relief Art in Wood: Why the CXC4 Majestic XL Pro Excels

Relief art involves carving a design that remains attached to a solid background, with elements that appear to be raised or recessed. Achieving a high level of detail in relief art requires a CNC router that can move with precision and stability.

The CXC4 Majestic XL Pro stands out because it provides the control necessary to manage both intricate patterns and fine details. The combination of its sub-50 micron accuracy and minimal backlash gearbox means that every cut is executed with unparalleled precision, ensuring that even the most complex designs are faithfully reproduced in wood.

Achieving Fine Detail in Sculptures

When it comes to creating small, rounded sculptures, the ability to precisely control the cutting tool’s movement is paramount. The CXC4 Majestic XL Pro’s advanced 4-axis capabilities allow the machine to execute smooth, continuous cuts, ensuring that curves and contours are accurate to the design specifications.

Moreover, the machine’s precision helps in maintaining the integrity of the sculpture’s details, preserving the subtle textures and fine lines that give a piece its character. Whether working on a miniature figure or a detailed ornament, the CXC4 Majestic XL Pro enables artisans to bring their visions to life with exceptional fidelity.

Ease of Use and Versatility

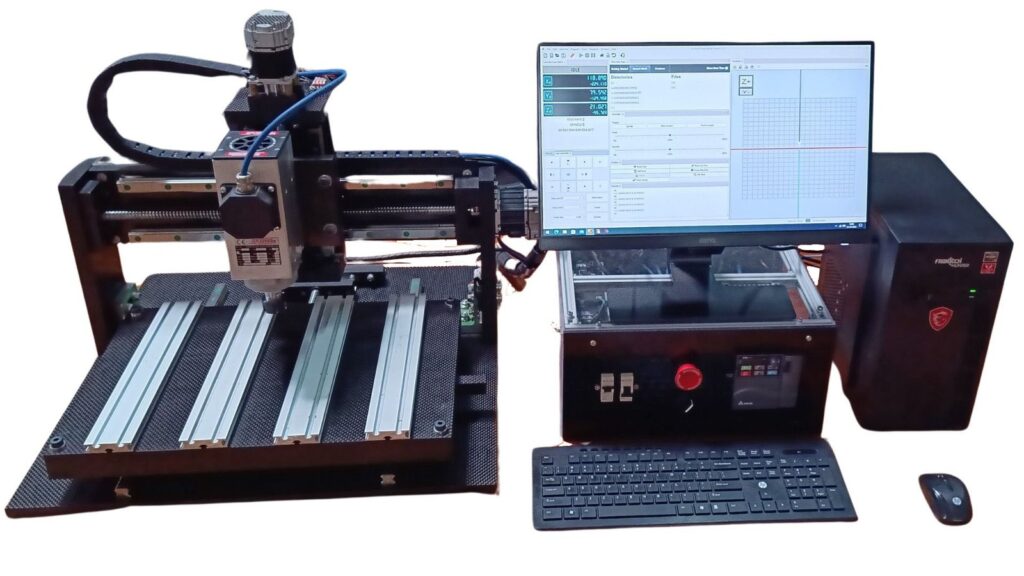

Despite its advanced capabilities, the CXC4 Majestic XL Pro is designed with user-friendliness in mind. Its interface is intuitive, allowing both beginners and experienced users to operate the machine efficiently. The versatility of this CNC router makes it suitable for a wide range of woodworking projects, from decorative pieces to functional components.

Software Compatibility

The machine is compatible with various CAD/CAM software, giving users the flexibility to design and execute their projects with ease. Whether you’re using industry-standard software or more specialized tools, the CXC4 Majestic XL Pro integrates seamlessly into your workflow.

Why Choose the CXC4 Majestic XL Pro?

With so many small CNC router machines for wood working on the market, it can be challenging to decide which one is right for you. The CXC4 Majestic XL Pro distinguishes itself by combining precision, power, and versatility in a compact package. It’s not just a machine; it’s an investment in quality, accuracy, and efficiency for your woodworking projects.

Key Benefits Recap

- Unmatched Precision: Sub-50 micron repeat positioning accuracy ensures that every detail of your design is executed flawlessly.

- Minimal Backlash: Less than 5 arc minutes of backlash guarantees consistency and reliability in every cut.

- Multi-Axis Capability: Full 3 and 4-axis operations allow for intricate relief art and detailed sculptures.

- Compact and Efficient: A small footprint optimized for speed and accuracy, ideal for workshops of all sizes.

- User-Friendly: Easy to operate, even for those new to CNC technology, with broad software compatibility.

Final Thoughts

When it comes to woodworking, especially in creating detailed relief art and sculptures, the right tools make all the difference. The CXC4 Majestic XL Pro by Akriti Precision Systems Private Limited is an outstanding choice for anyone looking to elevate their craft to the next level. Its precision, versatility, and ease of use make it a must-have for any serious woodworker. With this machine, you’re not just investing in a tool; you’re investing in the future of your craft.

Frequently Asked Questions (FAQs)

1. What makes the CXC4 Majestic XL Pro suitable for relief art in wood?

- The CXC4 Majestic XL Pro offers high precision with less than 50-micron repeat positioning accuracy, making it ideal for creating detailed and intricate designs in relief art.

2. Can the CXC4 Majestic XL Pro handle small rounded sculptures?

- Yes, the machine’s 4-axis capability allows it to create smooth, continuous cuts, perfect for detailed and rounded sculptures.

3. Is the CXC4 Majestic XL Pro user-friendly for beginners?

- Absolutely. Despite its advanced features, the machine is designed with an intuitive interface, making it accessible for both beginners and experienced users.

4. What software is compatible with the CXC4 Majestic XL Pro?

- The CXC4 Majestic XL Pro is compatible with a wide range of CAD/CAM software, allowing for flexibility in design and execution.

5. How compact is the CXC4 Majestic XL Pro?

- The machine is designed with a compact footprint, making it ideal for workshops with limited space, without sacrificing performance or accuracy.

6. Why is minimal backlash important in a CNC router?

- Minimal backlash ensures that the machine’s movements are precise and consistent, which is critical for achieving high-quality results in woodworking projects.