CNC machines have revolutionized manufacturing, enabling precise and efficient production of complex parts. But for businesses and educational institutions in India, the initial hurdle can often be the price of a CNC machine. Understanding the factors that influence this cost is crucial for making an informed decision.

This blog post will delve into the key aspects that determine the price of CNC machines in India, helping you navigate the market and find the perfect fit for your needs.

Factors Affecting CNC Machine Price in India:

- Country of Origin: The price of CNC machines in India can vary depending on the country of origin. European and American brands often carry a premium due to established reputations and higher import costs. Indian-made CNC machines, on the other hand, offer a competitive price advantage while maintaining quality standards.

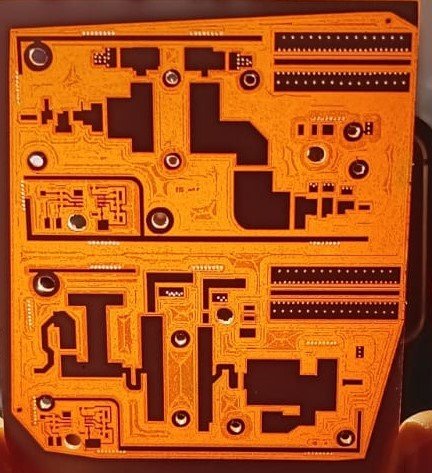

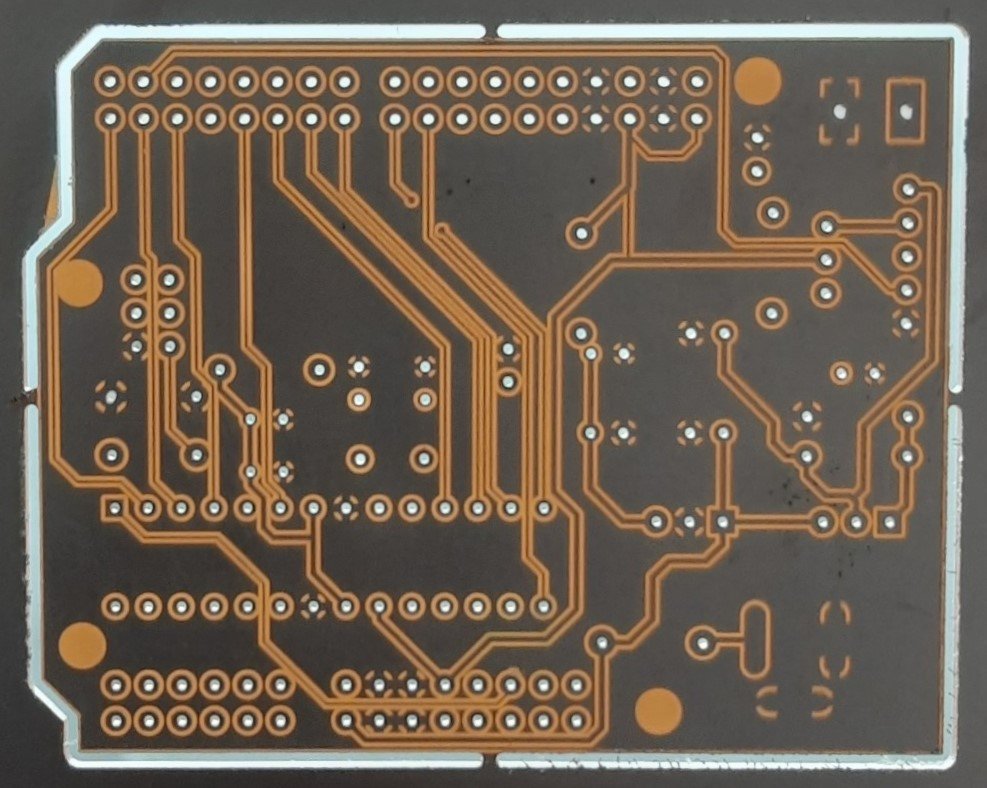

- Parts Used: The quality and brand of the components used in a CNC machine significantly impact its price. High-end controllers, motors, and other parts contribute to a higher overall cost.

- Precision Offered: The level of precision a CNC machine offers directly affects its pricing. Machines capable of tighter tolerances are naturally more expensive. Consider the level of precision required for your specific projects when evaluating price.

- Warranty: A longer warranty period indicates the manufacturer’s confidence in their product. While it may translate to a slightly higher initial cost, the extended warranty provides peace of mind and could save on future repair expenses.

- Service and Support: Reliable service and support are crucial for any CNC machine purchase. Look for manufacturers with a strong presence in India, offering readily available after-sales support and spare parts. This can save you time and money in the long run.

Great Options for MSMEs and Educational Institutions:

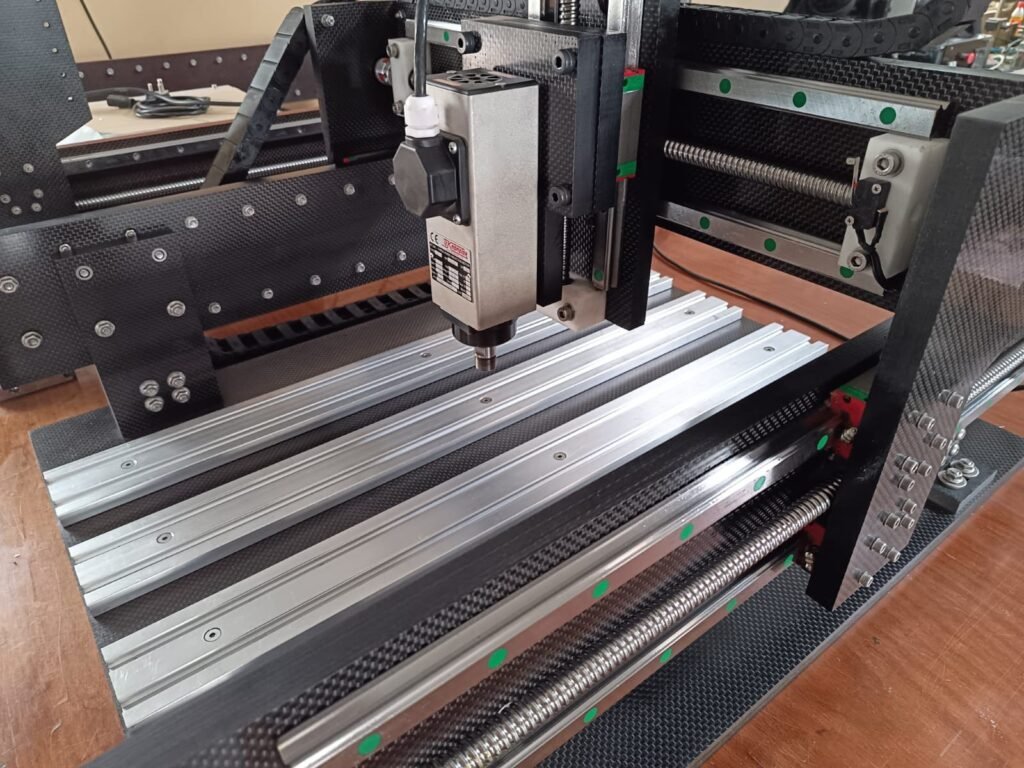

Akriti Precision Systems Private Limited, a Bangalore-based company (Website: https://akriti.tech), is a leading manufacturer of high-quality CNC machines in India. They understand the specific needs of MSMEs and educational institutions, offering:

- Competitive Pricing: Akriti leverages domestic manufacturing to provide cost-effective CNC machines without compromising on quality.

- Focus on Reliability: They use reliable components from established brands, ensuring smooth operation and minimal downtime.

- Suitable Precision Levels: Akriti offers a range of CNC machines with precision levels tailored for various applications, helping you find the right balance between functionality and budget.

- Comprehensive Warranty: Akriti provides a competitive warranty period, giving you peace of mind.

- Strong Service and Support: With a dedicated team, Akriti offers prompt after-sales support and ensures easy access to replacement parts.

By understanding the factors affecting the price of CNC machines in India and considering reputable manufacturers like Akriti Precision Systems, you can make an informed decision that fits your budget and project requirements. This empowers both businesses and educational institutions to unlock the potential of CNC machining and achieve their manufacturing goals.